|

Written/Photography by Albert V

When Jim from Just Jeeps called me up and inquired about building his Dana 300 for his rock buggy, I realized we have not given much attention to this tough little transfer case. A few years back we installed a 4:1 in our old CJ’s 300 and added the Currie twin stick option, but lately, it seems when it comes to ultimate t-cases, everyone has Atlas on the brain. I can attest that the Atlas may not be for everyone. Not only is it over $2000 US, it ended being much larger than I anticipated, and almost as heavy as a Dana 205 found in full-size trucks. I’ve experienced the weight more often than I care to during the numerous refits during our Krawler build.

The TeraLow 4:1 gear set from Tera Manufacturing has been very popular with off-roaders for quite a few years now. The three centre gears are the reduction gears while the two large gears on each end replace the drive gears to provide strength inside the Dana 300 t-case.  To add strength to the back of the t-case, Advance Adapters make a big rear output shaft kit. The shaft replaces the stock 26-spline output shaft with a larger 32-spline shaft (the portion that goes into the yoke is larger). With the addition of the larger shaft and the outside of the yoke, a replacement tail housing completes the package. The housing still accepts the stock speedometer cable too.

The Dana 300 came in Jeeps from 1980 - 1986, which was the last year of the CJ. There was also a version created for the International Scouts but you may want to avoid those units because they have a different mounting flange and will not work with most adapters and clocking rings. The 300 is more than acceptable in stock form behind mild V8s, but in today’s world of extreme low gearing and big horsepower the 300 can still be used and will stand up well with a few simple upgrades. For those with front pumpkins on the drivers side rather than the passenger side there are flip kits that are also available.

What makes the 300 so good? It has a fully cast case, is gear driven, comes stock with 2.6:1 low range, it’s compact and can be easily changed over to a twin stick for front wheel drive digging ability around corners. Add an index ring and it can be turned up and out of the way or like we mentioned, flipped over for driver’s side pumpkins. Its short length also works great for short wheelbase rigs. CJ’s were plentiful and lots of 300s can still be found. Add the fact that Advance Adapters has a ton of tranny options for in front of the Dana 300 and you can put one in almost any rig on the road today.

For the front of the t-case we turned to JB conversions. They offer a large 32-spline front output shaft kit to match the strength of the rear shaft.

In order to use the larger front shaft, the bearing retainer (which also holds the shift rails) will need to be machined to accept the larger.

There are some crucial gear measurements that will need to be taken when assembling the new front output shaft. With the gears on the old shaft, use a straight edge and feeler gauges to check gaps and clearances. Make sure the gaps are the same when installing the gears onto the new shaft.

In order to use the larger front shaft, the bearing retainer (which also holds the shift rails) will need to be machined to accept the larger. In order to remove the front bearing retainer, the two shift fork retainer screws must be removed from inside the case. The bearing retainer can then be pulled out of the case with the shift rails leaving the shift forks in the bottom of the case. You may need to hold the shift forks straight while pulling out the shift rails so they don't bind. In Jim’s case the process also included a complete tear down to install the Tera gears and AA rear output shaft.

While great in stock form there are plenty of aftermarket parts available to beef them up and lower the gearing. Both Tera and JB conversions have 4:1 gear sets, Advance Adapters and JB both have over-sized rear shaft kits and JB also had a heavy-duty front shaft.

For Jim’s rig we went with the same Tera 4:1 gears that had proved themselves in my Dana 300, the Advance Adapters rear 23-spline output shaft assembly and the JB Conversions front 23-spline input shaft assembly. Jim had already manufactured his own twin stick assembly.

All of these parts considerably strengthen the t-case and provide an excellent crawler gear set for rock crawling. With minor grinding the only major alteration to the t-case housing, the install goes as smooth as a standard tear-down and rebuild.

One note about the Tera gears: they start out pretty damn noisy because they cut the gears with very little clearance to minimize backlash and to help with shock loading when getting on and off the gas. For this reason the gears do take a few miles to break in and quiet down. After this time period and a fresh batch of gear oil, your 300 will be good for many years to come!

In order to clear the new larger gears inside the case, the Tera low kit comes with a new shift rail with a notch behind the detent impressions.

Not all the bearings inside the case come with a race. These needle bearings are loose and need to be installed into the new Tera gear. Some thick grease will need to be used to hold the bearings in the gear when assembling the t-case.

The physical diameter of the new Tera gears is much larger than the stock gears. Even with this size difference, not too much needs to be done inside the case to fit the gears inside.

In order for the new gears to slide in the case easily, a small amount of steel needs to be ground from this corner of the case. No material should need to be removed from the gasket surface – just from the rough casting inside the case. Tera mentions that a file can be used but if you have access to a die grinder or Dremel tool with a steel bit, it would work much easier. It will be necessary to use a press to remove some of the bearing inside the case. If you follow the instructions carefully, the process will be quite painless. Both the front and rear shafts come with new bearings to fit the larger components. All new seals come with the Tera low kit, but make sure any bearing you are re-using is in good shape – or get replacements.

When you add a clocking ring to the 300 the thickness of the plate means less engagement of the splines between the tranny and t-case this longer input shaft from Advance Adapters provides that extra spline area lost to the clocking ring.

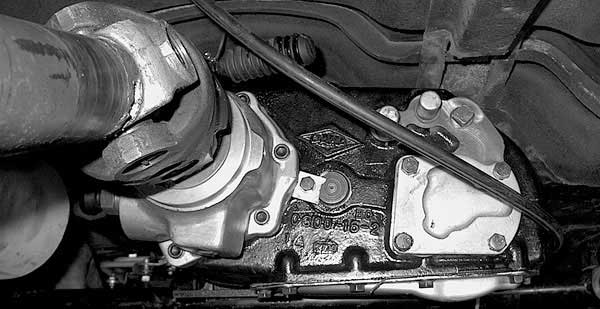

You can see that the new Advance Adapters tail shaft housing is much larger and stronger than the stock unit. The end of the case houses the large bearing that allows the use of larger-than-stock yokes. The front and rear of the Dana 300 can now use 1310, 1330 and 1350 yokes, though some machining on the yoke may be needed for 1350 yokes.

With the addition of a clocking ring the Dana 300 can now be repositioned for ultimate ground clearance. Jim managed to get his case completely flat in his rock buggy. Whether you are competing, want a tough case or just can’t fit an Atlas into the space you have, building up a Dana 300 would be the perfect upgrade for you.

4x4 Suppliers

|