|

Dahlberg Audio

Design. |

|||

|

This series of articles will describe the making of "The tall neodymium ribbon". The description is complete but is not intended for the absolute beginner. It takes some experience in handling with machines and a decent respect for the forces involved. The magnets used in this project produce

a substantial magnetic force so you better take care about your hands etc.

This first article will be about the magnetic system and some smaller parts. Part 2 describes some woodworking and the internal wiring. In the third and final part the manufacturing of the ribbons are described.

Thanks to Per "Pac" Adelson for input, help and publication at HiFiForum.nu | |||

|

I'm starting of with some background. I have constructed a number of ribbon

tweeters of different form and function over the last 15 years.

Almost all of them have shared similarities with the concept of the "Apogee Duetta",

a concept that is well suited for most people. This page on the other hand

will describe the construction of a more advanced neodymium

based tweeter. |

|||

|

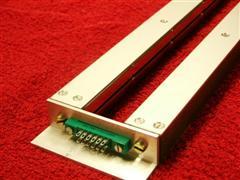

Finished result without the ribbon. | |||

|

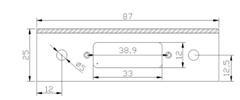

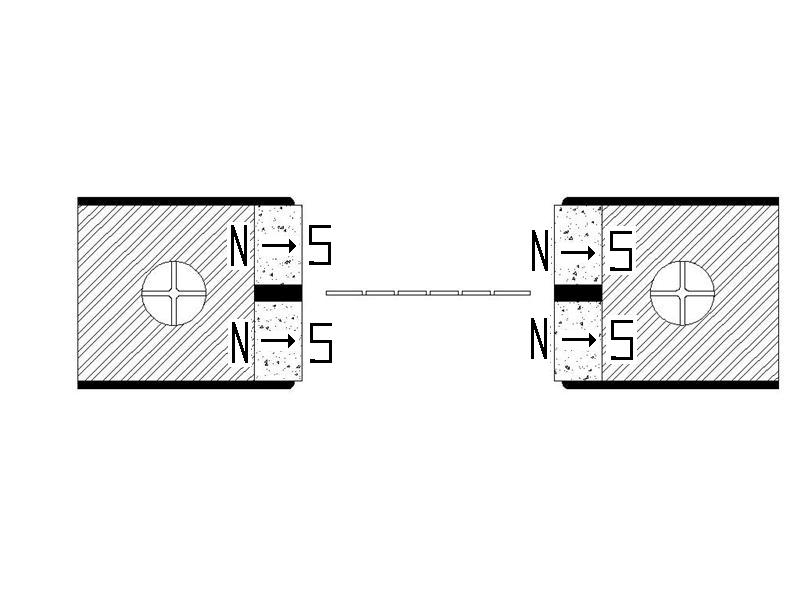

This is how they look in theory. | ||

|

|

|

| |

|

Magnets |

Aluminum strips, 22x22mm steel and angled profile from aluminum. | ||

|

| ||

|

Card edge connector. |

Some tools are also needed | ||

|

First cut the steel to the right length, a hacksaw is recommended. Take some measurements on the magnets just to be sure about the length. Calipers made from plastic are good enough and they are non-magnetic, that's not insignificant. If the steel rods turn out to be a little bit short, that's not a problem it's almost an advantage. Adjust the length with spacers. It's important that the cuts are perpendicular. T | |||

|

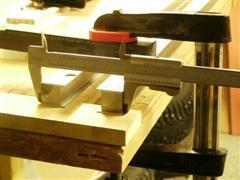

Now the aluminum strips are mounted. After a thorough cleaning of the

steel you will sand two sides for improved bonding. I'm using both

adhesive and bolts. The strips should also be sanded for the adhesive.

Nothing strange about the gluing just make sure the strips don't slide. A

lot of extra work is thereby avoided.

|

|

| |

|

Don't glue the parts to the table the first thing you do. Notice the wooden rods. |

| ||

|

| ||

|

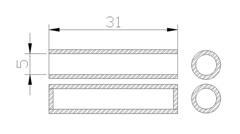

Drill 2,7 mm through all of it and thread M3 from both sides. |

Countersink. | ||

| |||

|

The two holes on the left have to be there because of the holes that will be drilled for the short ends. Also it improves strength where it's needed the most. | |||