Dahlberg Audio

Design.

"The

tall neodymium ribbon". Part 2 |

|

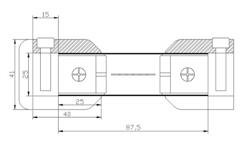

Now we are down to woodworking. The drawing on your right shows one of my

latest constructions in profile. The shaded area is detachable and in this

version also mounted to the magnetic circuit (those bolts are not in the

drawing). The black lines show speaker-fabric. You will need it, strangely

enough not even grownups can keep there fingers to themselves. There are

two measurements that say 25mm and that makes it easy for the construction

of a gluing, and routing jig. Just use a one inch square steel

pipe of sufficient length.

The steel pipe has to be cleaned and

painted to prevent it from discoloring the wood during gluing.

Apart from what's showing in the drawing

some connecting parts will be made. For starters some blocks 87x25x15mm

preferably from the same wood. 25

and 15 is not absolutely crucial. Some covers over and under the opening

to finalize it. Here you can use almost anything just as long as it isn't

magnetic. |

|

|

The finished result as a drawing. |

|

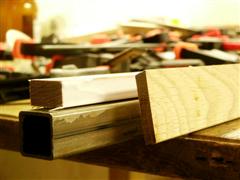

We

are starting of with some "U-profiles", these ones are made from

oak.

Use appropriate amounts of regular white wood glue. Don't leave

it for to long or else the glue may stick to the steel pipe. 30 minutes is

sufficient.

|

|

|

|

"U-profiles" |

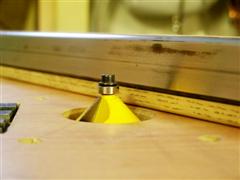

You

will need some tools... |

|

|

|

These ones work so-so but they are fast |

You

can take a little of before routing. |

|

When that's done it's time for routing and that will be done

with the pipe as a guide. Some hand tools may also come in handy. The

pictures should be helpful enough when describing how to do this. Simulate

the routing before you start the machines and please be careful about your

fingers.

|

|

|

| Copy routing. |

Angled routing. Make sure that you measure carefully. |

|

|

|

Ok. |

|

The last part of the "U-profile" will not be glued.

Instead it's attached with screws. To get the right drilling depth I'm using a little helper,

look at the pictures. When that's done you just finish of the routing.

Same procedure as last with the steel pipe in place. |

|

|

| Some marking. |

Drill with depth limitation. Barely through the first layer

but no more. |

|

|

|

Ok,

now it's time to turn the parts into a left end right side tweeter/driver. On the

outside you are supposed to glue an additional 8mm strip of oak. Due to

the fact that the drivers are supposed to be a mirror imaged pair it's

quite important to keep track of how you are putting it all together. Lay

them side buy side, it helps.

Gluing is done without the detachable part of the

u-profile. At this point you will have to use the clamps again, you

can not get to many of these. Just keep it up as earlier, appropriate

amounts of glue and look closely at the pictures about how too set the

clamps. Access glue is easily removed later with a sharp knife.

The

angled routing is not done on this profile yet but is still possible.

after the next moment it's not so take care of this now. Just as earlier

with the steel pipe and so on. Now it's time to glue the wooden blocks that are

holding the two halves together. |

|

|

|

Widening of a U-profile. |

Set a few clamps to eliminate the risk of sideways

slipping as well. |

|

|

|

The blocks are made from what's left of earlier bits and pieces.

88x15x26mm will work just fine. Let the magnetic circuit lay in place

during assembly, that way you are sure that it will fit later on. Once

again, keep track of what's left/right and up/down. |

|

Blocks,

88x26x15mm. Just the 88mm's that are important. |

The u-profiles are glued together, keep track of left/right

and up/down. |

|

|